Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 30 março 2025

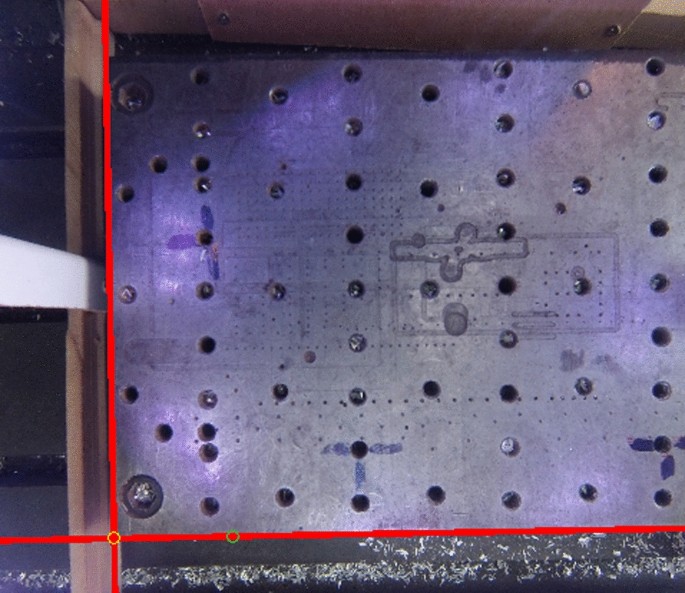

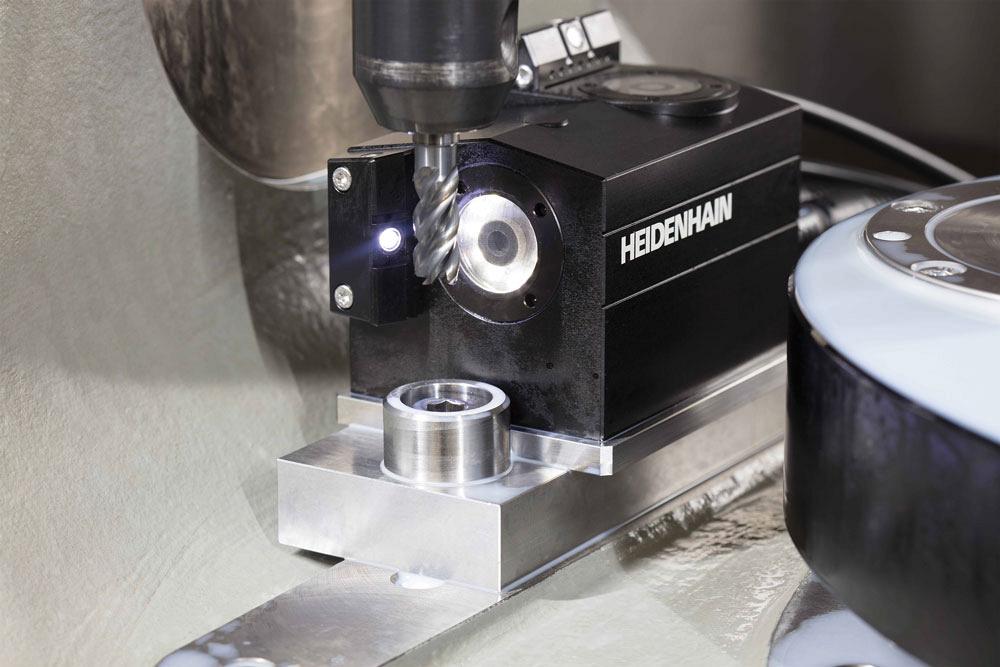

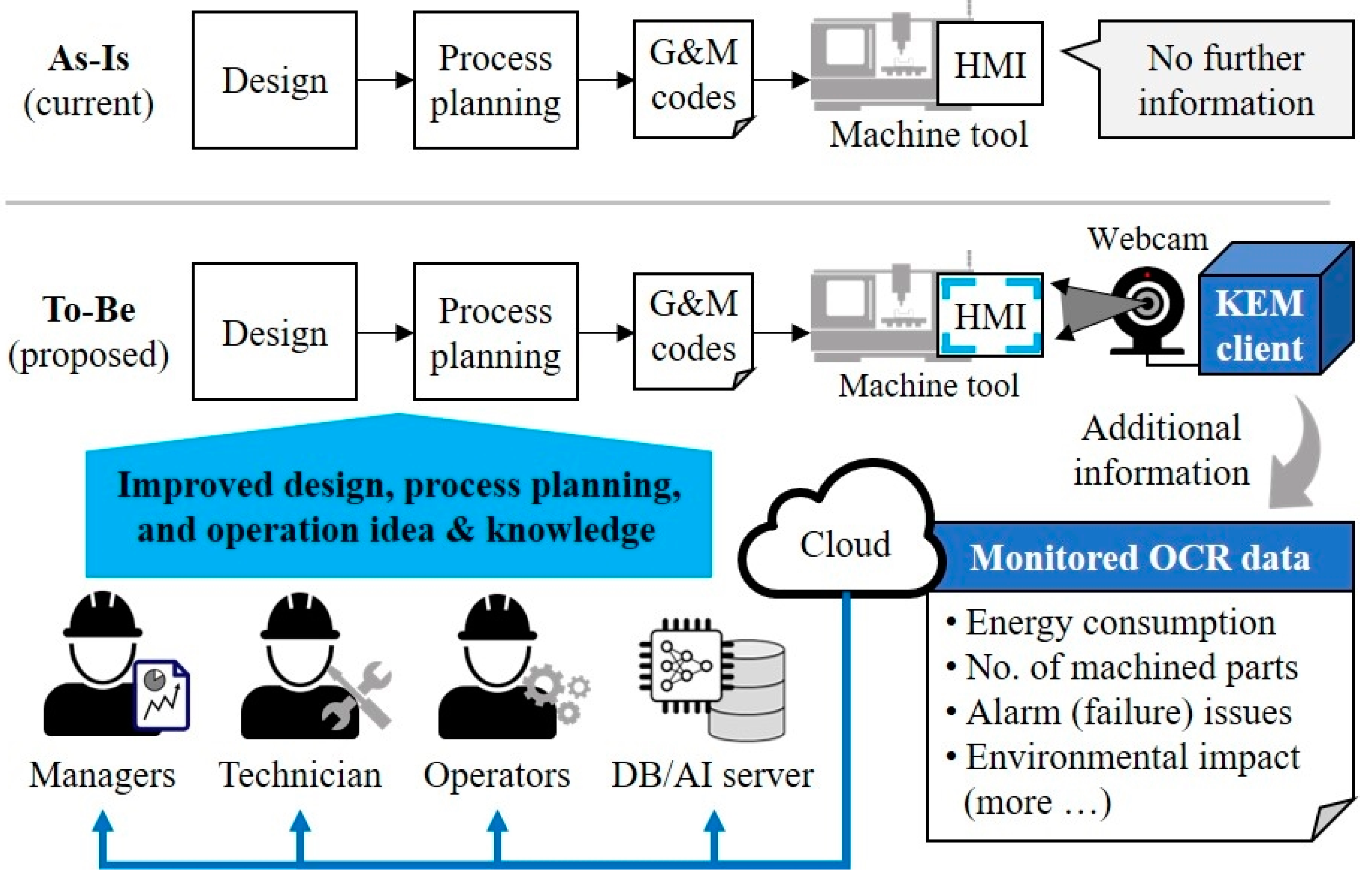

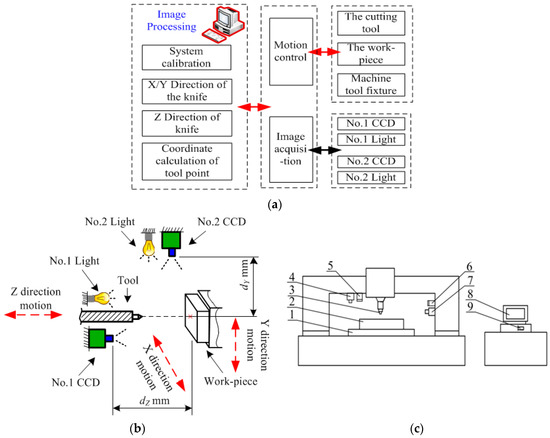

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

Development of a computer vision-based system for part referencing

What is next for 5-axis CNC technology?

What is next for 5-axis CNC technology?

GitHub - mikeroyal/Computer-Vision-Guide: Computer Vision Guide

5 Axis CNC Machining: Types, Applications, Benefits, and Design

Robotic Integration

How is 3D Machine Vision helping to Transform the Manufacturing

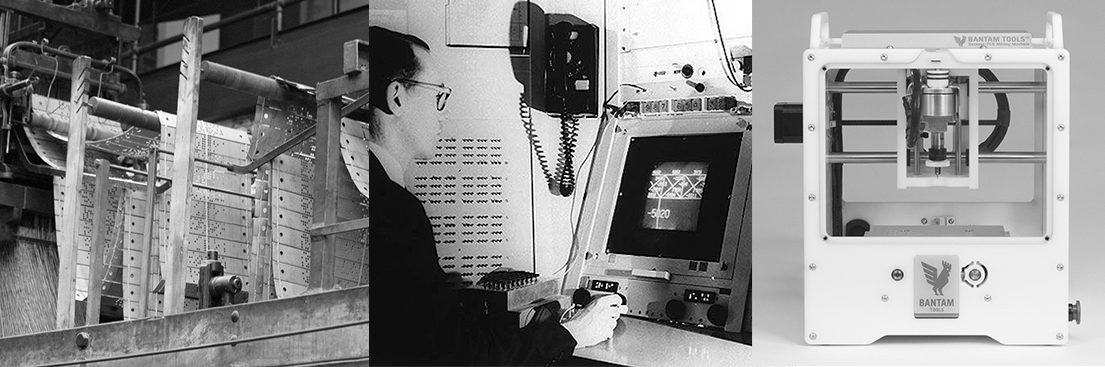

History of CNC Machining. Part 1: The People, Stories, and…

Arc1Cnc

ABB launches breakthrough robot alignment software increasing

Interest in Robotic Automation for CNC Machine Shops Increasing

Sensors, Free Full-Text

How is 3D Machine Vision helping to Transform the Manufacturing

Sensors, Free Full-Text

Keyence Inspection System Review - Kremin, Inc

Recomendado para você

-

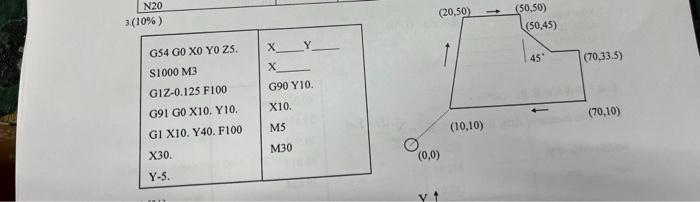

Solved N20 3 (10%) (20,50) (50,50) (50,45) X Y 45 (70,33.530 março 2025

-

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z30 março 2025

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z30 março 2025 -

Porsche Guards Red, 80K / 84A / M3A / G1 / G830 março 2025

Porsche Guards Red, 80K / 84A / M3A / G1 / G830 março 2025 -

Tấm Flat 100mm F100-G1 - HNC Deco Moulding30 março 2025

Tấm Flat 100mm F100-G1 - HNC Deco Moulding30 março 2025 -

About - Hudlow Axle30 março 2025

About - Hudlow Axle30 março 2025 -

Mancal Lado Coletor Belina G1 Corcel G1 F100 F350 F600 F750 Até 01/10/30 março 2025

Mancal Lado Coletor Belina G1 Corcel G1 F100 F350 F600 F750 Até 01/10/30 março 2025 -

![LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD](https://images.craigslist.org/00C0C_6MdecwLenMC_0CI0pI_600x450.jpg) LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD30 março 2025

LAST PRICE]PC with TV-box i5-6400/8G DDR4 Ram/New 256Gb NVME SSD30 março 2025 -

G1 Autobot Optimus Prime Truck Red with Robot on Chassis from30 março 2025

G1 Autobot Optimus Prime Truck Red with Robot on Chassis from30 março 2025 -

Thermaltake Pacific DIY LCS Black G1/4 PETG 16mm (5/830 março 2025

Thermaltake Pacific DIY LCS Black G1/4 PETG 16mm (5/830 março 2025 -

Simultaneous extrusion of two extruders filament · Issue #862030 março 2025

Simultaneous extrusion of two extruders filament · Issue #862030 março 2025

você pode gostar

-

Gta v ps3 midia fisica +42 anúncios na OLX Brasil30 março 2025

Gta v ps3 midia fisica +42 anúncios na OLX Brasil30 março 2025 -

Freecell Solitaire Blue30 março 2025

Freecell Solitaire Blue30 março 2025 -

Penteado Infantil com amarração e tranças fáceis para escola30 março 2025

Penteado Infantil com amarração e tranças fáceis para escola30 março 2025 -

thickvalley Relógio mecânico de xadrez, cronômetro profissional de xadrez com 2 mostradores grandes, o tempo pode ser definido arbitrariamente, temporizador de competição portátil para xadrez chinês, xadrez internacional, jogo de tabuleiro30 março 2025

thickvalley Relógio mecânico de xadrez, cronômetro profissional de xadrez com 2 mostradores grandes, o tempo pode ser definido arbitrariamente, temporizador de competição portátil para xadrez chinês, xadrez internacional, jogo de tabuleiro30 março 2025 -

Overwatch 2 Season 3 Will Feature the Game's First IP30 março 2025

Overwatch 2 Season 3 Will Feature the Game's First IP30 março 2025 -

⚘ ⦂ Zoro in 2023 Zoro one piece, Zoro, Live action30 março 2025

⚘ ⦂ Zoro in 2023 Zoro one piece, Zoro, Live action30 março 2025 -

Slideshow: 10 cenas inacreditáveis de Velocidade Furiosa30 março 2025

Slideshow: 10 cenas inacreditáveis de Velocidade Furiosa30 março 2025 -

Call of Duty: Modern Warfare 2 Remastered reportedly arrives tomorrow (Updated)30 março 2025

Call of Duty: Modern Warfare 2 Remastered reportedly arrives tomorrow (Updated)30 março 2025 -

Legacy Of Discord Elite BR 🇧🇷30 março 2025

-

Bobby Fischer, El Mas Grande (Paperback)30 março 2025

Bobby Fischer, El Mas Grande (Paperback)30 março 2025